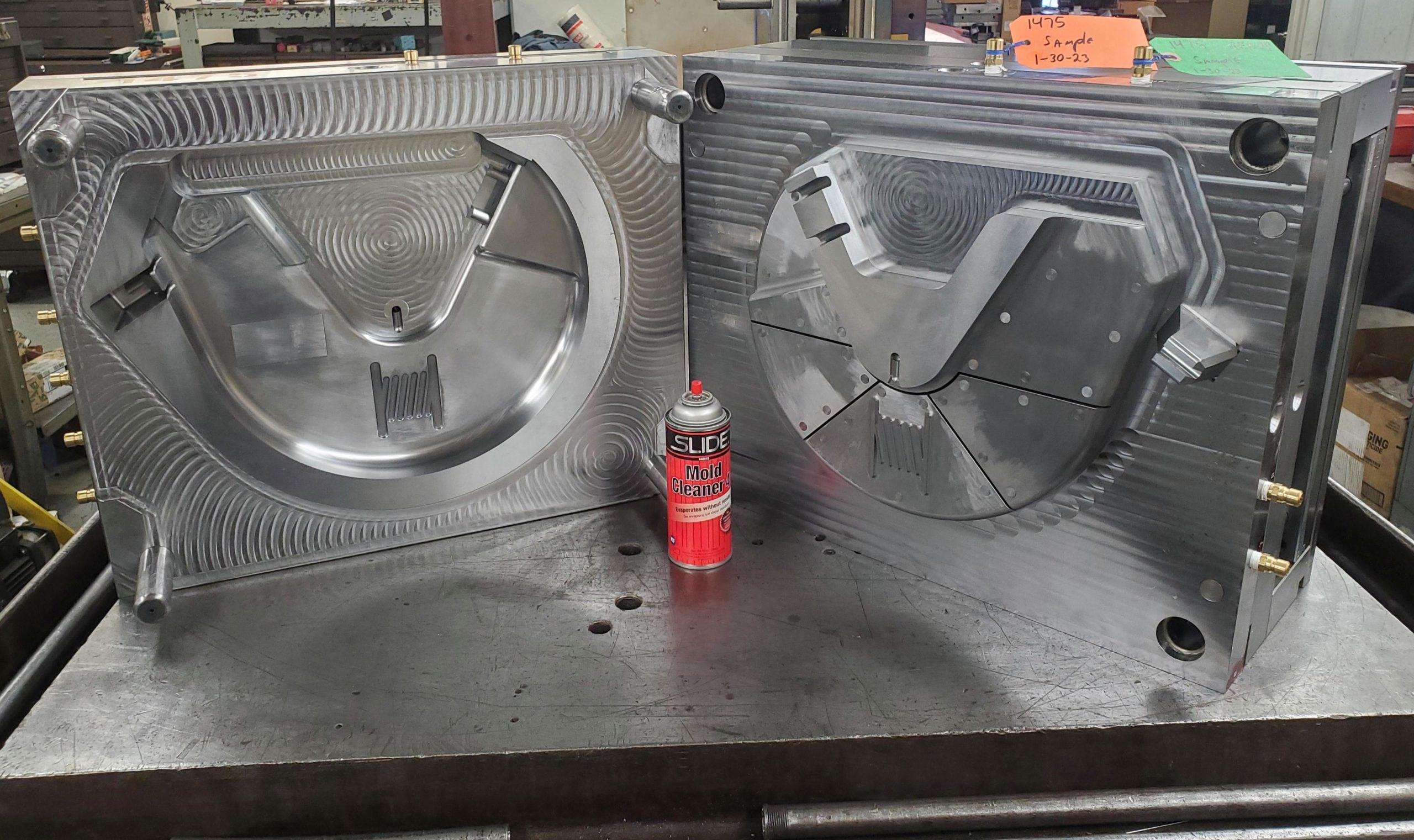

Why Transfer a Tool?

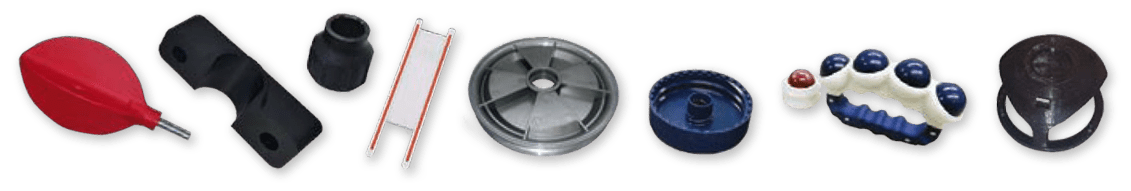

Many manufacturers are seeking ways to improve efficiency, reduce costs, lower freight expenses, and enhance product quality. Transferring existing molds to a new manufacturing partner can be an effective solution. The question becomes what does transferring tool a really involve, and when does it make the most sense. Transfer tooling involves relocating existing injection molds from one manufacturing partner to another. Companies consider this move for a variety of reasons, such as:

- Reducing production costs by partnering with a more cost-effective supplier

- Overcoming capacity or quality limitations at a current facility

- Improving part consistency by leveraging advanced equipment or specialized expertise

- Moving operations closer to end markets to reduce lead times and shipping costs

When managed effectively, tool transfers can lead to improved product quality, streamlined operations, and significant long-term savings. At Chenango Valley Technology, we specialize in making the mold transfer process smooth and stress-free. A great reason to transfer your tool to CVT is our on-site tool room. Most molders do not have a full-service tool room. Ours is ready for repairs and revisions to keep your job in production. When a mold breaks down during production our tooling staff is here to have the mold operating in hours or a few days. Not days, weeks-months like our competitors. Often with routine maintenance and PMs free of charge. Contact us today about injection mold tooling transfers with a company that has your bottom line as a priority.