Offering In-House Capabilities

Part Design

Every customer and project or part that we work with is unique. However, we use our experience to assist you in designing a cost-effective part for your project.

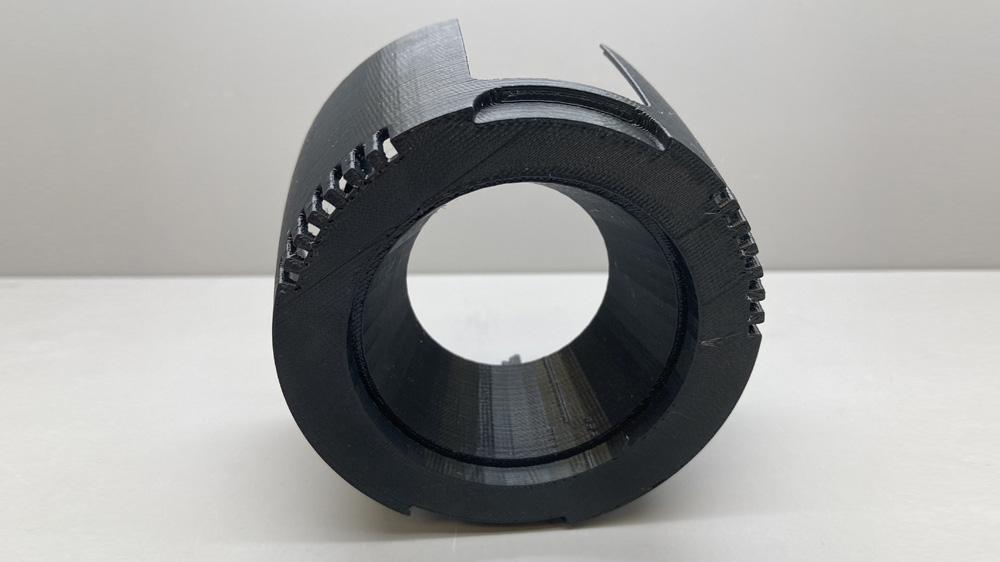

3D Printing / Prototyping

Working with the latest in 3D Printing industrial technology, we can quickly test your product right here in-house.

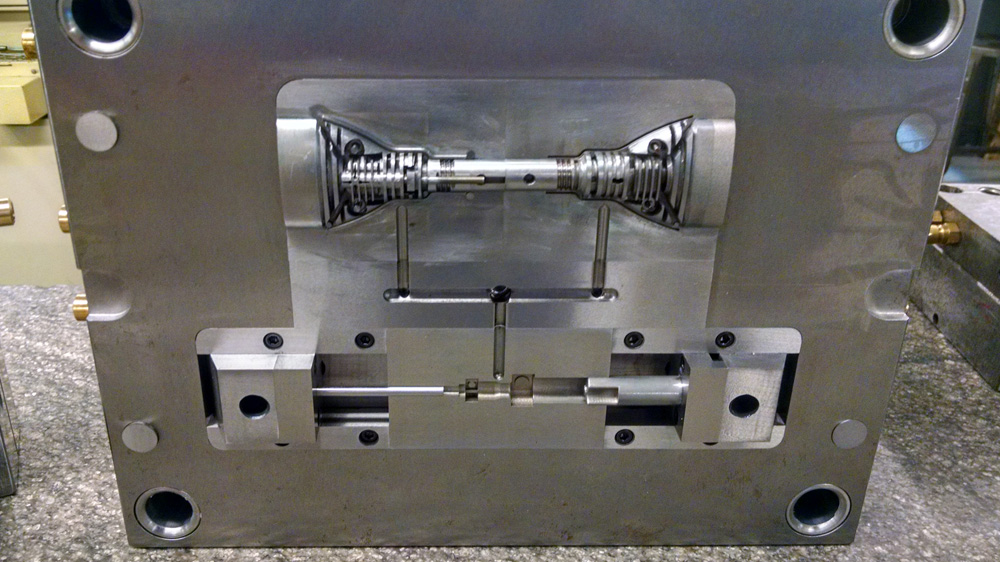

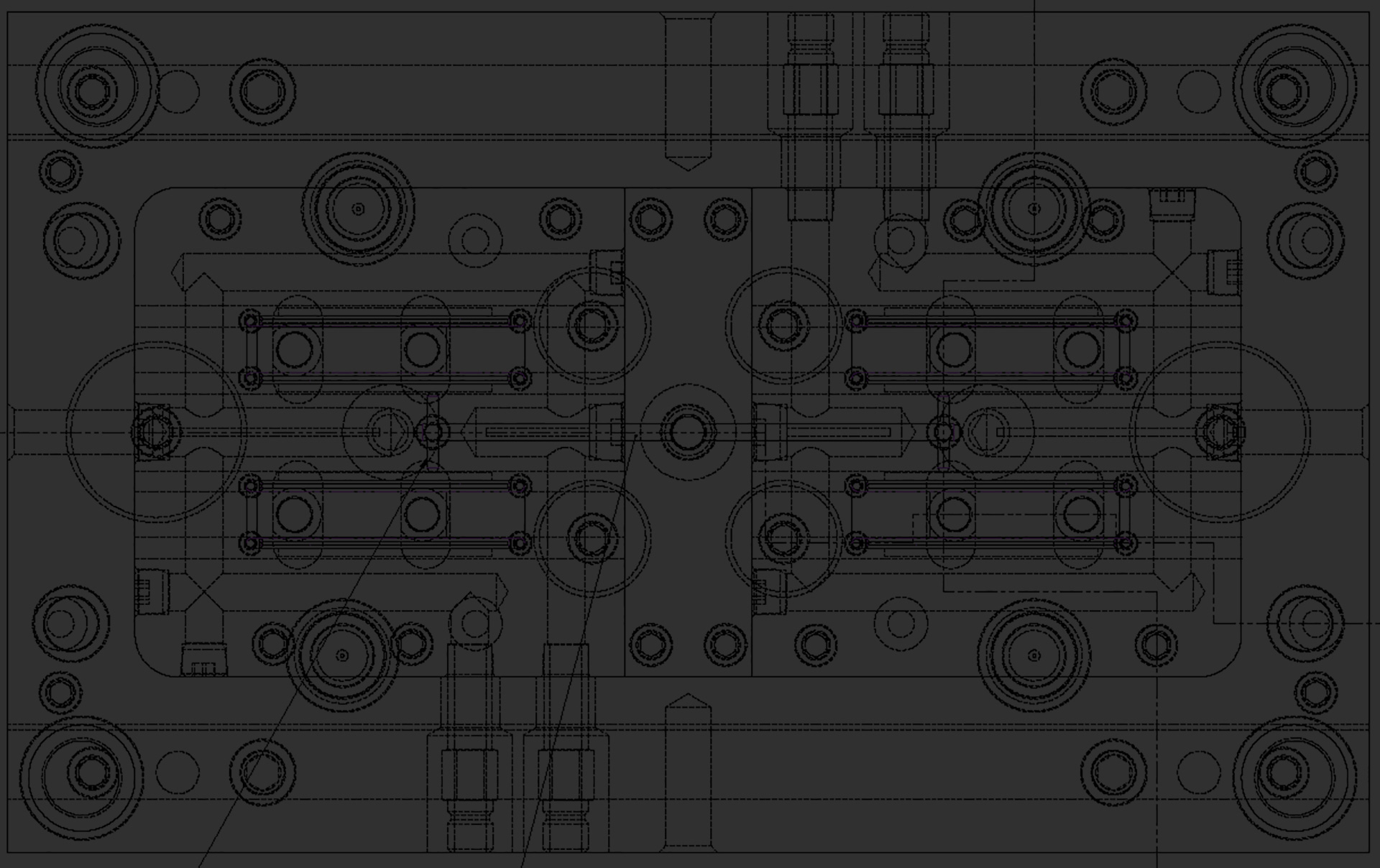

Mold Design

With a group of experienced engineers, material specialists, and operational specialists, we can design a mold that will meet your production needs.

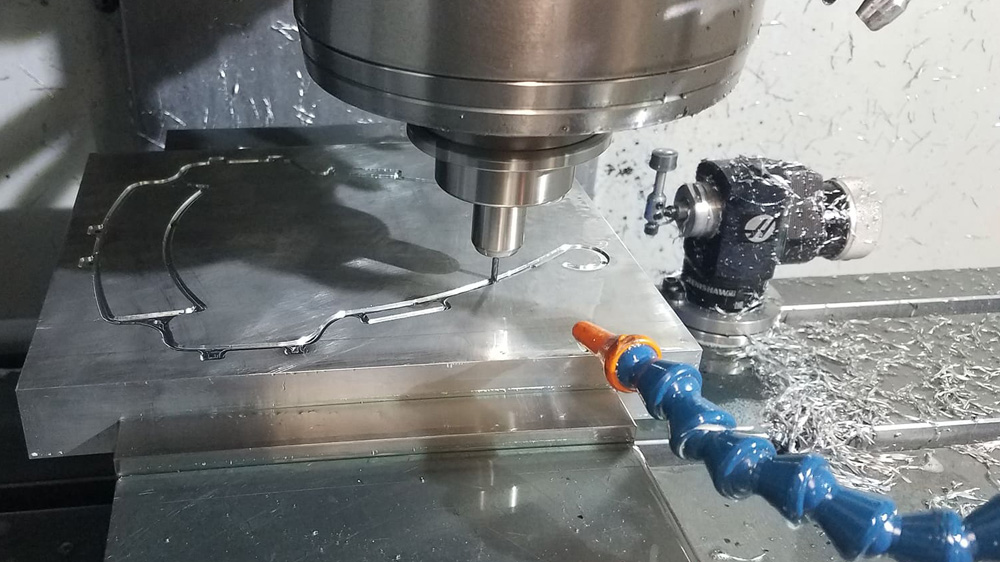

Mold Making

With an adept tooling crew and a state-of-the-art tool room, CVT uses precision and experience to create reliable and high-quality molds for everything and anything our clients can imagine.

Rapid Mold Making

Our staff has a vast amount of experience allowing us to complete molds in record time. Using our experience, CAD-CAM Technology, and options available, we can turn your molding project quickly should your needs require it.

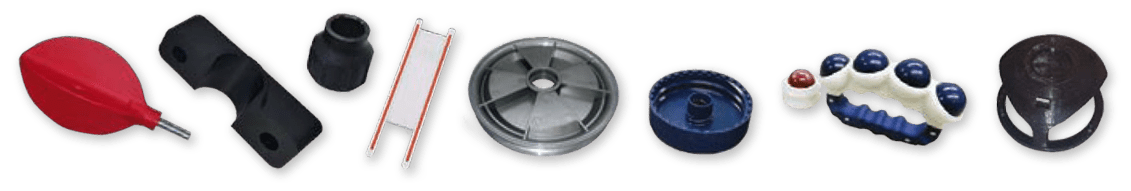

Injection Molding

With 23 injection molding machines ranging from 20 to 500 ton clamping power, we can meet the needs of any plastic parts manufacturing.

With 2 Modern Facilities for Design & Tooling and Injection Molding

Our Facilities

Our Process

Every situation is unique. We are here to help you with the process of taking your idea from paper to production with what you need.

3 Step ProcessQuality You Can Trust!

CVT is dedicated to the ongoing improvement of our quality system and continuous elevation of our quality standards.

Quality Control

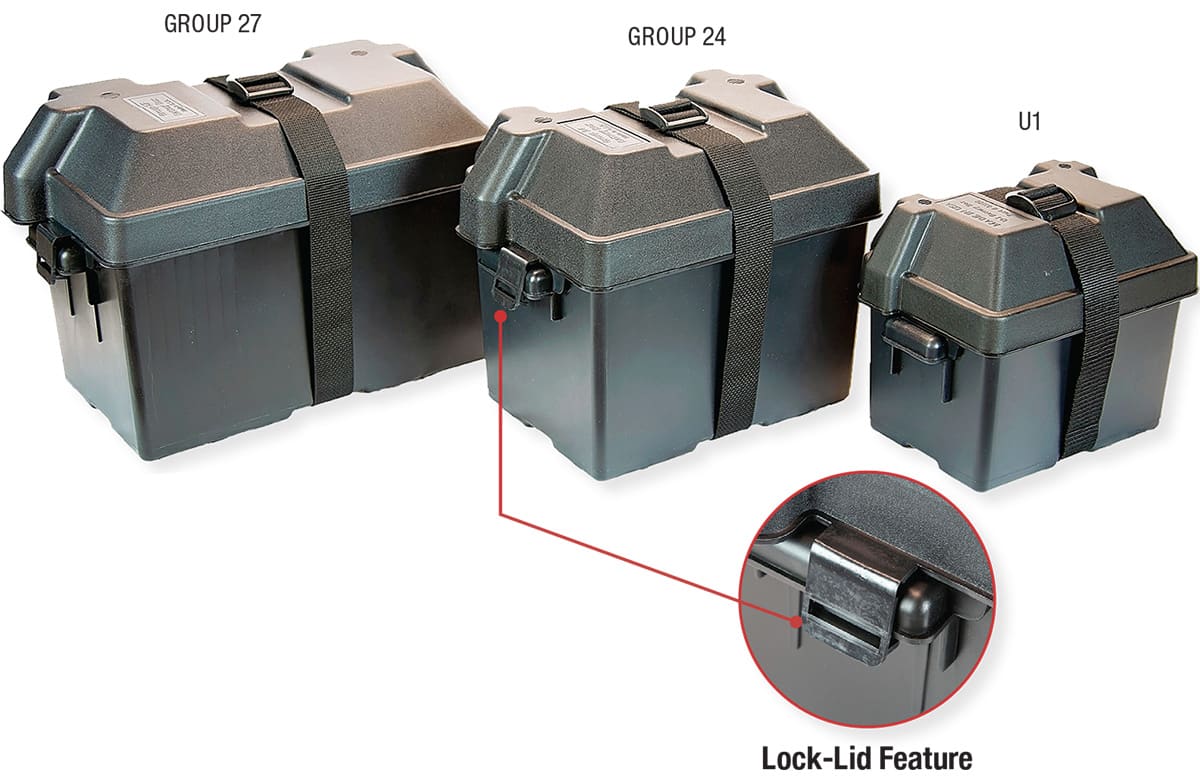

Battery Box & Tray

For use in RV, Marine, Lawn & Garden and Specialty Power Equipment Markets

Product Specs